Applying Value Engineering:

Methodology and Industry Applications

In 1947, design engineer Lawrence Miles pioneered Value Engineering (VE) while searching for raw material substitutes at General Electric. This innovative approach was crafted to optimize product functions, ensuring essential performance while minimizing lifecycle costs. Today, VE is a cornerstone in new product development and enhancing operational efficiency, continuing to shape industries globally, including the built environment.

Value Engineering, also known as Value Analysis (VA), employs a systematic method to improve the value of a product or operation by focusing on its essential functions. The primary goal is to achieve the desired performance at the lowest possible lifecycle cost*. VE integrates principles of creativity, organized planning, and precise analysis to enhance efficiency and minimize unnecessary expenditures.

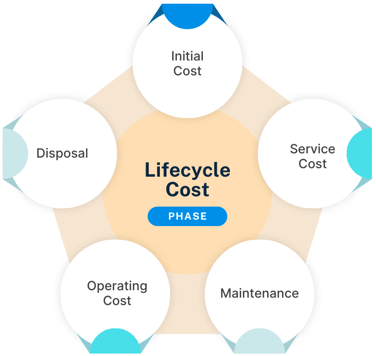

Lifecycle Cost:

Lifecycle cost is important because it encompasses not only the initial cost but also the subsequent costs incurred during the operation and eventual disposal of the product.

Particularly in the construction industry, VE proves critical as it addresses both the cost-effectiveness and performance optimization of building projects. By applying VE, professionals in the built environment can ensure that every element of a project—from materials to construction techniques—delivers maximum value without sacrificing quality or functionality. This makes VE especially valuable in today's market where efficiency and sustainability are paramount.

The key principles of Value Engineering revolve around three main elements:

|

|

|

|

Lifecycle Cost. Lifecycle Cost. |

What is "Value"?

In Value Engineering, "value" isn't just about cost. It's defined as the ratio of a product's functionality to its lifecycle cost, encapsulated in the formula V=F/C. This metric focuses on maximizing functionality while minimizing costs, aligning with the consumer preference for "high quality at low price."

Defining Functionality

Functionality in VE goes beyond basic operations. It refers to the essential roles a product or service performs, designed to efficiently and effectively meet specific needs. This is the core of a product’s utility, directly impacting its performance and usefulness.

Understanding Cost

Cost in VE represents all expenses from the inception to the disposal of a product or service, including both direct financial outlays and broader resource utilization. This comprehensive view helps stakeholders understand the total investment over the product’s lifecycle, emphasizing efficient resource use.

Applying Value Engineering in the Construction Sector:

A Systematic Approach

In the construction sector, VE involves a structured, step-by-step decision-making process that aims to enhance project value by optimizing functions and minimizing costs:

|

Select the Value Engineering Object |

|

Collect Relevant Information |

|

Carry Out Functional Analysis |

|

Put Forward Improvement Ideas and Formulate Improvement Plans |

|

Analysis and Evaluation Plan |

|

Feasibility Test |

|

Check the Implementation Status and Evaluate the Results |

Electrifying Value Engineering: Applications in the Electrical Sector

In the electrical sector, VE is crucial for optimizing systems to enhance efficiency and reduce costs.

Applications include:

- Smart Grid Technologies: Improving grid operations through advanced technologies that enhance energy distribution and efficiency.

- Renewable Energy Integration: Utilizing VE to assess and integrate renewable energy sources like solar and wind, ensuring they provide maximum efficiency at reduced costs.

- Essential Design: Applying VE to redesign electrical systems and components to reduce materiality without compromising functionality.

- Sustainable Lighting Fixture Selection: Using VE to audit lighting fixture selection in regards to embodied carbon and ensuring that performance criteria is still being met.

- Reduction in Transportation: Select products to consolidate transportation methods and costs while still maintaining specification requirements.

Value Engineering's principles ensure projects across all industries achieve optimal functionality at minimized costs while fostering innovation and quality. By applying these principles, significant improvements can be realized in project outcomes, especially in sectors like construction and electrical where precision and efficiency are crucial. VE not only supports firms in maximizing resources but also in achieving sustainable growth, proving that the foundational principles established by Lawrence Miles continue to resonate and impact modern industries profoundly.

Enhancing these efforts, Parspec's Product Finder is a transformative tool for the VE process. It leverages AI to rapidly identify spec-compliant products, optimizing the Bill of Materials by efficiently matching project specifications. This tool simplifies the task of data collection and analysis, which are pivotal in VE, by automating the extraction of technical requirements and facilitating quick, accurate product selection. Such capabilities ensure that Value Engineering is not only about sustaining quality and reducing costs but also about streamlining efficiency in every project phase.

.png?width=5504&height=1356&name=Colored%20Logo%20(1).png)